Whether you require 25 pieces or 25 million pieces, IDI Fabrication staff will work with your company to develop a cost effective process that will provide parts that meet all of your expectations.

Our extensive manufacturing capabilities feature a number of competitive advantages in part production.

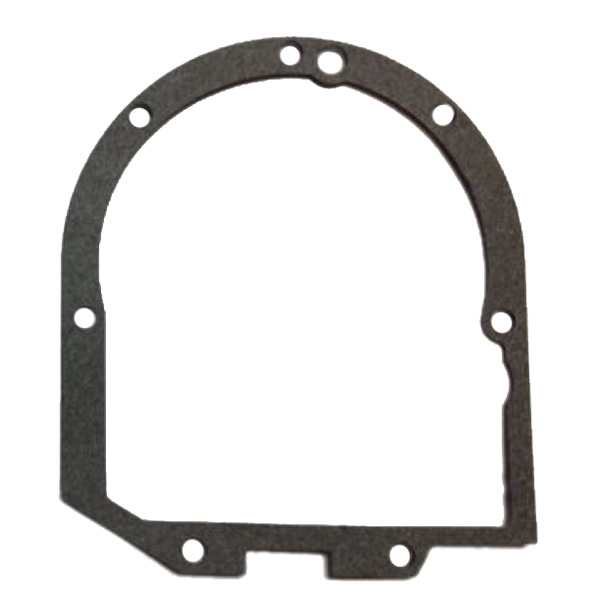

- Ranging from 15 to 120 tons, our presses allow for the production of precision components at high production rates in rigid laminates and thick films.

- These presses allow for the cost-effective production of low to medium volume products in thin laminates and thin flexible materials.

- Application of adhesives to varying substrates and lamination of various materials are also a feature of these presses and processes capabilities.

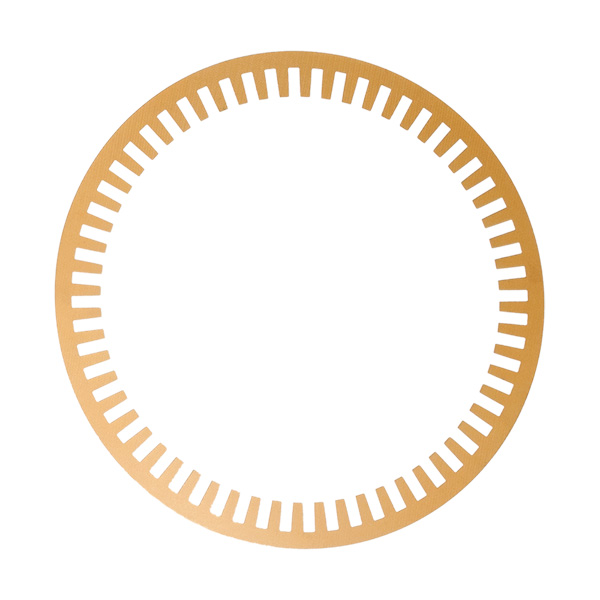

- This process allows for the production of low to high volume products in thin material and flexible composites.

- Parts can be cut into individual pieces or can be placed on a liner and remain in roll form for ease of use in the production environment.

- Application of adhesives to varying substrates and lamination of various materials are also a feature of these presses and processes capabilities.

- All tool designs are created in house with the most up-to-date-software available. Maintaining design in house provides the tightest control in accuracy and assures that our customers' expectations are met the first time every time.

- Most tool construction is performed in house to assure the highest quality, shortest lead times and the lowest cost possible.

- In house capability also provides security in that if a tool is damaged or needs maintenance, it can be repaired and back in production in the shortest time possible.

- Full converting capabilities in house from primary material preparation including slitting, laminating, sanding and sheeting; to part finishing operations including coating, dying and baking, assures reduced lead times and purchasing cost advantages for our customers on the most complex applications.